Doing less work to be more productive. This seems counterintuitive, yet it’s one of the core underlying principles of Kanban, the project-management system for visualizing work and reducing waste.

Jon Terry, COO and cofounder of Kanban software maker LeanKit, explained what it takes for any organization to do Kanban. “Step one is the visual management aspect, using visual signals to allow employees to run their own work. Step two is going to be looking at it and saying, ‘If we’re going to be better at doing things, we need to limit how much we’re working on.’ So, limiting our work in progress (WIP)” is the next step, he said.

Reducing WIP eliminates bottlenecks often seen in projects and blocks the ideal of a continuous stream of deliverables, he explained.

After visualizing work and limiting WIP, the next step would be to do analysis on the data (such as cumulative flow of work, and cycle time) that the Kanban board provides to improve the system at work, to enable a freer flow of work as opposed to a batch-and-queue, schedule-based system, Terry said. These techniques help organizations define their real capacity for work.

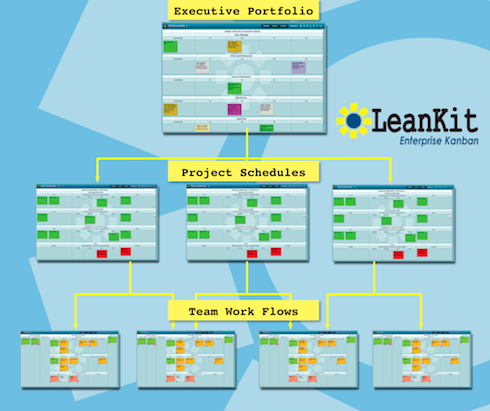

LeanKit has recently released an update to its LeanKit Kanban Professional Edition called Portfolio Kanban, which the company said supports enterprise portfolio management at any scale. This enables a manager using one board to delegate a card (representing a project) to a team using another board. That card can then be broken down into many smaller tasks, with the relationship between the card and tasks maintained.

Terry said that, in truth, an effective Kanban board will automatically help you limit WIP, because you will eventually run out of space on the board. “If you build a board with five lanes, and lane three is chock full of work to the full board, the WIP starts getting limited automatically because there’s just no more place to put sticky notes,” he said.

“The truth is, what teams tend to find is that limiting it more than that is going to be better. Eventually, they’re going to arrive at some number lower than the ‘lane is chock full’ that will produce better results.”

LeanKit also improved the look and feel of the management tool, moving away from what Terry called “a lovely shade of gray” to something much more visually pleasing, he said. More importantly, perhaps, is the change of the home screen from a text list of boards to a visual dashboard that displays a snapshot of each board that that moment.